Project Description

Characteristics of the equipment

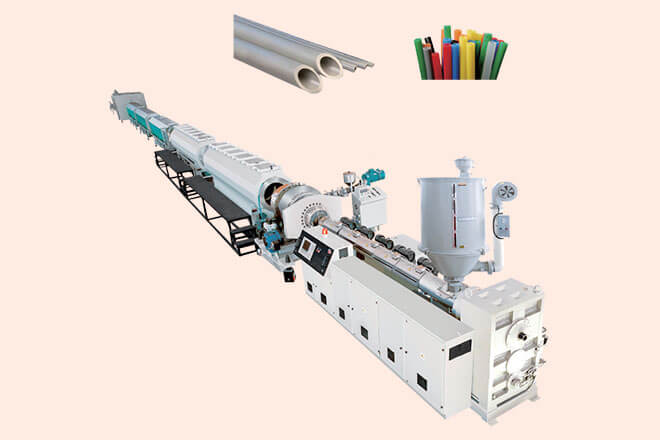

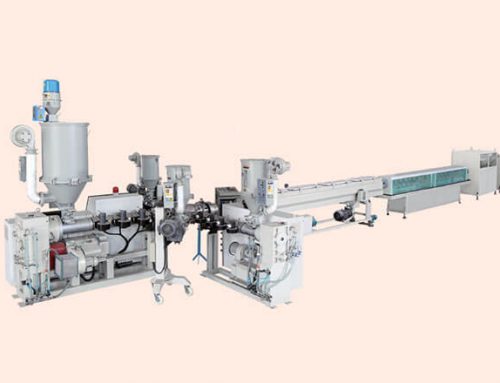

This line is made by the advanced technic from Germany and designed as the high efficient extruder according to the producing characteristics of PP-R, PP-B, PE-RT and PEX, and consists of high torque gearbox, new type slotted barrel with the high output, low melting temperature and realize the Iow temperature plastifization indeed.

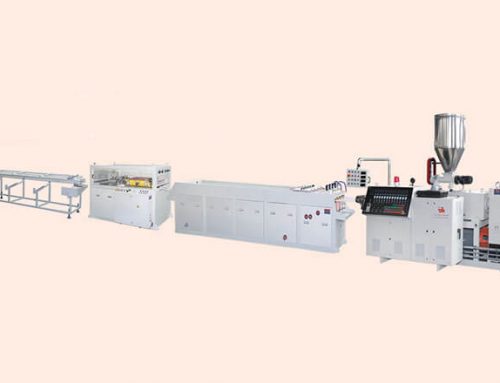

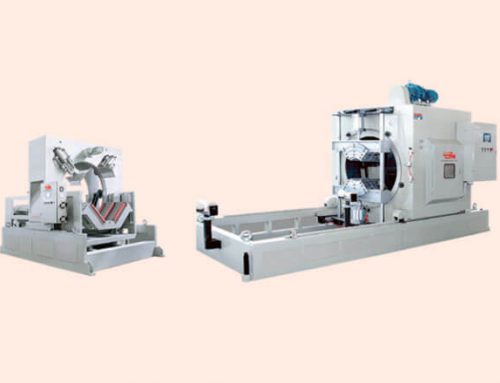

The line can produce the PP-R and PP. B pipe with high speed. And its products have been reached the standard of GB/T- 18742.2-2003 approved by China State Chemical Test Center. PE-RT and PEX pipe reached the standard of GB/T18992.2-2003. The production line consists of control system, extruder, die head, vacuum calibration unit and haul-off and cutting units, printer and Stacker and pipe collector. The die head adopt lattice or spiral mould and can suit for the static mix system. Special vacuum calibration unit and spraying cooling bath: two section vacuum calibration unit, perfect water temperature, water lever and flow rate contort to guarantee the pipe products with high quality. After simply changing the section of line, e g. Different dies, screws and other accessories, it can also produce PE,ABS.PE-RT and PEX pipes and over two kinds of materials combining plastic pipes. High lever machine apply the PLC and color screen to be the control system with high automatization.

PE/PP/PPR/PERT Pipe Production Line

| Pipe diameter | 16-63 | 75-160 | 110-250 | ||

| main extruder | 45/33 | 60/33 | 60/33 | 75/33 | 75/33 |

| Die head | Single outlet |

Single outlet |

Single outlet |

Single outlet |

Single outlet |

| Down-stream equipment |

LG63 | SLG63 | LG160 | LG160 | LG250 |

| Total power | 70 | 90 | 130 | 150 | 225 |